The Cyclo One is a folding helmet now in the works by a team based out of London. What makes the Cyclo unique is that it is made from 100% recycled plastic, some of which is pulled from the ocean and landfills. It also packs fairly small and is expected to be relatively affordable.

The Cyclo is expected to ship in March 2020, so stay tuned. We will update this post as soon as we get our hands on it.

About the Cyclo

Sustainability

What we know so far about the Cyclo is that it is made out of recycled plastic– each helmet has the equivalent of about 20 plastic bottles. To help fight for removal of plastic from the world’s oceans, Cyclo is partnered with Plastic Oceans, an advocacy group on plastic pollution (and producers of the documentary A Plastic Ocean, called “one of the most important films of our time” by Sir David Attenborough). Cyclo has also partnered with Green Wave Plastics to supply recycled ocean and landfill plastic to be used in the helmet.

While most helmets are made primarily out of Expanded Polystyrene (EPS) foam, the Cyclo is made out of recycled High-Density Polyethylene (HDPE). That’s the same material used to make milk jugs, bottles for laundry detergent and shampoo, motor oil bottles, ice cube trays, and tons of other things. In addition to being made from 100% recycled HDPE, the helmet itself is also 100% recycleable.

By using recycled materials– especially those coming from landfills and oceans– not only does the Cyclo avoid adding unnecessary plastic waste, it also reduces it.

Safety

What makes the company’s decision to use HDPE interesting is that, aside from being sustainable, it leads to a significant redesigning of the basic helmet formula.

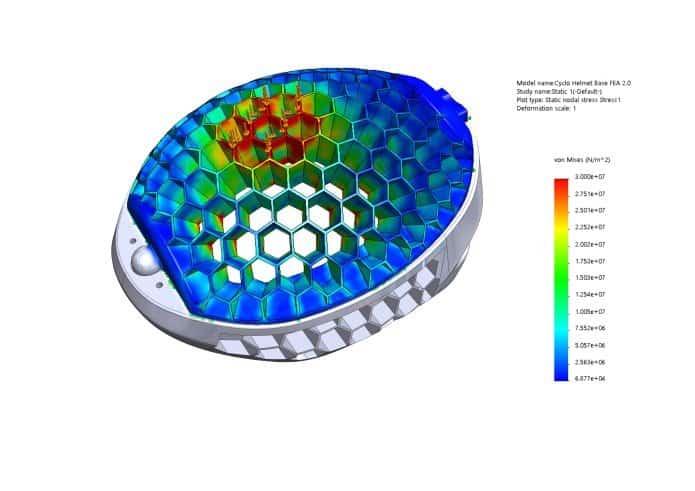

Basically, an EPS helmet works differently from a helmet made of a firmer plastic like HDPE. While an EPS helmet is filled with tiny air bubbles which pop and crack on impact to absorb shock, the HDPE-based Cyclo is not inherently shock absorbing and therefore must dissipate the force of the impact in a different way.

EPS foam

HDPE honeycomb lattice on Cyclo helmet

For an ordinary EPS helmet, the lining, or shock absorbing part, is essentially the same thing as the white foam packaging you find in the box when you buy a new appliance– it’s no doubt effective at insulating the appliance from outside shocks.

But because of the firm, dense HDPE the Cyclo is made from, its creators approached it in a different way. Rather than design the helmet to take the full impact locally, they used a honeycomb lattice to dissipate the energy laterally. The creators claim that this alternative design means significantly less energy is transferred to the head, and makes the helmet 68 percent more effective at impact control.

According to Dom Cotton, Cyclo’s Chief Marketing Officer, the Cyclo “draws inspiration from bees… They make great use of that familiar, hexagonal structure which forms the very strong foundations of their hives. This honeycomb design has been integrated into planes and rockets since the 1950s due to its protective, yet light-weight, qualities.” Indeed, the basic hexagonal design used by Cyclo has been used in all sorts of high-stress applications from the Hubble Space Telescope to snowboards.

Another potential bonus of the firmer plastic is that the Cyclo may end up being multi-impact– meaning that a minor crash would not necessarily result in having to throw out the helmet, unlike a standard EPS helmet. (Most helmets, which are lined with EPS foam, have to be thrown out if they ever get in even a minor accident, due to potentially hidden faults in the brittle plastic, but since the Cyclo is not made with EPS it may not have this problem.)

The Cyclo has already undergone over 100 hours of crash simulation, and is expected to meet both EU and US/CA safety standards. Here is the Cyclo doing a “drop test” on their own test rig:

Packability & Affordability

While safety and sustainability are non-negotiables for Cyclo, to help the helmet meet casual cyclists’ needs, they also took on two other goals: packability and affordability.

As this is a site for things that fold, we will look at its folding ability in detail later on, so keep reading.

In terms of affordability, the Cyclo is expected to cost under $100. At that price range, the Cyclo would be less expensive than the average folding helmet. Of course, we’ll have to wait until the Cyclo actually hits the market before we know for sure.

Recommendation

We’re waiting for our Cyclo to arrive in March 2020– until then, here are just our initial thoughts:

Overall, we are cautiously optimistic about the Cyclo.

It is above average in terms of:

- Environmental impact

- Price

- Compactness, or packability

- Portability

We think it is below average in:

- Ease of folding

We will elaborate on these further down.

Who the Cyclo Would Be Perfect For

We think there are two good reasons for buying the Cyclo over another folding helmet:

- Sustainability. The Cyclo is made from 100% recycled plastic, some of it recovered from landfills and oceans, and is 100% recycleable.

- Most packability for the price. If you’re looking in the $100-and-under range, no other helmet folds nearly as narrow as the Cyclo.

Foldability

The Cyclo is built as a three piece configuration, which the company calls the “flip clip system”. The top of the helmet and the bottom of the helmet are separate pieces, which are connected by a ball and socket joint in the front. There is a lever clip in the back which locks the pieces together.

To fold the helmet, you have to pull up the lever, swivel the top part of the helmet into the bottom part, and then re-close the lever. The entire process seems fairly quick and easy, and probably takes only a few seconds. In terms of folding time and difficulty, we think the Cyclo will be slightly below average compared to other folding helmets.

When folded, the Cyclo is just under 3″ wide. It folds narrower than most other folding helmets, especially in its price range. Its folded dimensions would be narrow enough to slide into a briefcase together with a laptop.

Open

Folded

The Cyclo design is still being finalized, but here is what we estimate the dimensions to be:

| Open | Folded |

| 11″ l x 8.5″ w x 6.5″ h | 11″ l x 8.5″ w x 2.9″ h |

Portability

By portability, what we mean is how easy it is to carry the helmet around in the hand or in a backpack once the helmet is folded.

The three criteria we mainly look at for portability are:

- The helmet’s weight

- How well it stays shut when folded

- How easy it is to grasp in one hand

Overall, the Cyclo is more portable than most folding helmets, since it locks shut and is easy to grip.

Weight

The Cyclo is expected to weigh 0.88 lb (400g), which is about average for a folding helmet.

Stays Shut

It is hard to carry a folding helmet around when part of it is dangling out. But the Cyclo is expected to stay firmly shut when folded, thanks to the lever clip in the back which secures the parts tightly together.

Easy to Grip

The Cyclo seems to have plenty of places from which to grip it, so we’re not worried about it slipping out of our hands.

Fit

In terms of sizing, the Cyclo will be made for a head circumference of 21.25″ to 24″, which should cover most people.

Comfort

Once the Cyclo is officially released and we have a chance to try it on, we will update this section with how the helmet feels.

In terms of ventilation, the Cyclo takes advantage of the large gaps in the honeycomb lattice to let air in as you ride. By the looks of it, the helmet appears fairly open and airy, so it should have decent ventilation.

Options

The color choices have not been officially decided yet, but Cyclo has stated that they are considering Black, Green, Tan, and Coral as possible options.

Summary

The Cyclo is projected to come out in March 2020, at which point we will have a better idea of what to expect. As the company is still 3D printing prototypes and gathering feedback, we can not yet be sure what the final design will entail.

What we know so far is that the company behind the Cyclo is committed to making the helmet sustainable, packable, affordable, and safe. If the company can achieve these goals, we would recommend the Cyclo as the most compact and sustainable folding helmet in its price range.

Cyclo images credit: Cyclo Technology on Indiegogo [https://www.indiegogo.com/projects/cyclo-packable-helmet-made-with-recycled-plastic]

EPS foam image credit: Wikipedia [https://commons.wikimedia.org/wiki/File:Polistirolo.JPG]

Your information is out of date. The Cyclo design has changed significantly as the designers had over-promised and under-delivered. The honeycomb didn’t meet impact standards, so that pattern is now only cosmetic on the top, with a thin exterior grid and an EPS liner for shock absorption. They admit to having problems raising enough money for production. Probably also because the honeycomb would have been too expensive to produce. All those deep holes pointing radially inward would have needed an astonishingly complex mold because of all the variously angled undercuts, not to mention ensuring the flow of the molten plastic through such a complex maze would have been a nightmare. It’s easy to 3D print just about any shape, not so much with production processes. They should have brought in a plastics engineer early on in the process, but relied on an in-house industrial designer instead. It didn’t help that this helmet was designed to be injection-molded, the most expensive process, mainly because you need tool steel molds to resist the high molding pressure. Steel molds for the original honeycomb design would have cost at least several hundred thousand dollars. Aluminum molds for simpler EPS helmets are a lot cheaper. I don’t think this will ever make it to the market. I’m going to buy a Closca Loop instead. Proven technology, already on the market and packs just as small.

Hi Ja Linn, thank you so much for your comment! You’re right, our information about the Cyclo needs to be updated. As you know, the Cyclo has had significant redesigns every few months since it first launched on their campaign page, so keeping this page updated with the latest information has been a challenge. When the Cyclo was first announced, we were surprised about the honeycomb design as well, since non-folding helmets that began with the honeycomb design such as the Hexr have had difficulty with that simple design as well, and had to rely on 3D printing with an EPS exterior, and cost a lot more. Hopefully your comment will provide some helpful information for people considering pre-ordering the Cyclo.